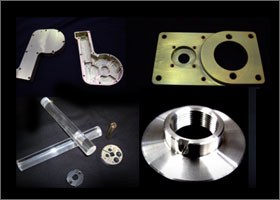

Precision CNC Machining

“CNC milling, CNC turned parts, CNC Grinding & Wire Erosion all at competitive prices”

We manufacture and stock hundreds of line items for our customers and use deliver-to-stock arrangements or max./min. stockholding systems to achieve optimum manufacturing quantities.

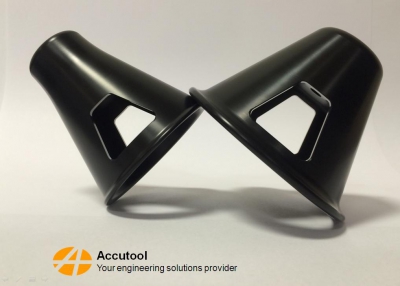

Our technologists develop CNC programs choosing the best tooling, fixturing, tool paths, and machining parameters to achieve high-speed machining, quality parts, and assemblies at competitive prices with on-time delivery.

The very latest in CNC technology is used in our machine shop permitting us to manufacture a wide range of components and productsto your drawings. Accutool has more than a quarter of a century of experience producing parts for a broad spectrum of industry sectors.

Have a look at our Manufacturing Capacity section for our equipment list.

We produce large volume projects of 250,000 parts per year on a contract basis with quality parameters better than 1.5 CPK.

Engineering quotations are based on activity costing at various hourly rates and include recovering costs such as programming time, skilled machinist set up time, semi-skilled machine runtime, off-machine operations time such as deburring, helicoiling, part marking etc. This results in a combined price reflecting the used technology, the complexity of the part and the quantity per production run.

Material and finishing services are purchased from qualified vendors through our quality management system ensuring full traceability and certification.

Our preference is to utilize CAD Drawings sent by email or if possible to download from an Ftp site.

In this regard can manage various types of file formats for file transfer.

Please have a look at our Gallery.